How to avoid tearout when routing with templates

Although the problem of tearout can sometimes be reduced with a slower speed, there are other factors, such as cutting depth, grain direction, and the cutting angle of the tool, that play a larger role.

When using any cutting tool you'll experience less tearout by taking two or more smaller cuts rather than one heavy cut. This is also true when using a shaper or router. When using a template and guide bearing to shape a profile on curved stock you can lighten the cut by using a larger guide bearing for the initial pass. Then switch to a smaller guide bearing to complete the cut. If you are simply flush trimming curved stock you can lighten the cut (and minimize tearout and cutting resistance) by first bandsawing very close to the layout line. This reduces the amount of stock to be removed by the router or shaper to a minimum.

However, depending on the grain and the type of wood you may still have small amounts of tearout that are not acceptable in fine work. Amana has developed several tools that address the problem of tearout when flush-trimming curved stock. Let's take a closer look.

However, this cutter has a 1-1/4" bore that I bush down to fit the 1" spindle on my shaper. And I don't recommend that you bush it down to fit a 1/2" spindle shaper; that is just to much load on such a small machine.

As I'm sure that you know, you'll get better results when jointing or planing stock if you cut in the direction of the grain. This also holds true when using a router or shaper to flush-trim a curved surface.

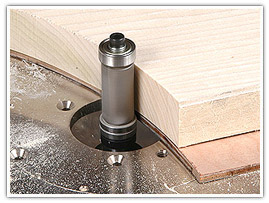

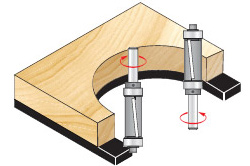

You can use this technique with the Amana Down-shear Multi Trimmer no.47097. This unique flush-trimming router bit has guide bearings at both ends. You can cut from either direction using only one template and without moving the template to the other side of the workpiece.

Another option is to use the Amana Ultratrim Spiral Trim bit. This tool also produces glass-smooth cuts and the extra long two-inch cutting length is enough to cut the thick stock that you're working. Spiral router bits are available in "up-cut" or "down-cut" configurations. Because I prefer to use a router table when flush trimming, I use the "up-cut" bit no.46304. The cutting action of this bit is safest when using a router table because it pulls the stock downward toward the table.

Finally, whatever tools that you choose to use for flush-trimming curved stock, remember to keep safety at the forefront. Use a guard to provide a barrier between your hands and the cutter. And position your hands a safe distance from the cutting action.

Related Items:

View all Trimming Router Bits