I want to say thanks againfor the great experience of the Woodworking Essentials Class. My wife insists that I make a matching table. I recall you had a jig for starting The dovetail joints in the drawer front and the top of the legs. Could you please provide a few details on the jig so that I can duplicate it?

By the way I ordered the Tambor Door Bit set. I intend to try the Bread Box project. I am looking forward to The Turning Class later this year.

-Bill N.

Kingsport, TN

Our Expert

Many woodworkers choose through dovetails over half-blind dovetails

because half-blinddovetails are more time-consuming to cut;

all the waste from between each pin must be laboriously chopped by hand with a chisel and mallet. But there are times, such as in drawer construction, when a half-blind dovetail is the best option. Unlike a through dovetail, the half-blind dovetail is revealed on only one face; this makes it thebest choice for drawer fronts andfinecasework. Half-blind dovetails simply have a cleaner appearance because, unlike a through dovetail, theylack thedistracting row of rectangles (the ends of the tails are hidden from view).

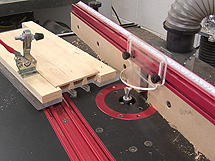

When cutting half-blind dovetails by hand, I avoid most of the labor-intensive chopping by first routing the space between the pins with the Amana Tool no.45852 dovetail bit and a shop-made jig.The bit has a guide bearing on the shank which follows the "fingers" on the jig.

The work is trapped in the jig on three sides and I secure the work in thjig from the top with a toggle clamp.

The work is trapped in the jig on three sides and I secure the work in thjig from the top with a toggle clamp.

Notice in the photograph that I use the fence on the router table when routing the pins. Although the fence does not guide the cut, it provides a place to mount the guard as well as a port for dust collection. Also, for safety reasons, always rout from right to left against the bit rotation

After routing I square the inside corners between the pins by chopping with a chisel and mallet. Then I mark the tails from the pins and saw the tails by hand in the usual way. The result is joint with all the features of a hand-cut dovetail, yet with considerably less time and effort. When making the jig, I first layout the pins to create the size and spacing that I desire.

Then I mark the location of each finger on the jig using thepin board to guide me. Keep in mind that each finger must be at least 1/4" wide to pr

event breakage. In order to make narrow pins (which are one of the signatures of hand-cut dovetails), I make the jig wider than the stock. After routing, I reposition the stock in the jig and route the board a second time. A strip of wood placed in the jig next to the stock fills the void during routing and prevents the workpiece from shifting sideways.

The work is trapped in the jig on three sides and I secure the work in thjig from the top with a toggle clamp.

The work is trapped in the jig on three sides and I secure the work in thjig from the top with a toggle clamp.