The application I'm working with is applying a beaded edge treatment to cabinet face frames that include a curved arch in the face frame.

Cutting a 3/8" diameter bead on the concave curved face of a gently arched face frame has me stumped. The only option I have used so far is a beading router bit on a shaper for the straight vertical elements and using a hand beading tool to cut the bead on the face of the curved elements. I haven't cut any miters where the vertical elements meet the curved arch of the face frame, instead I use carving chisels on the vertical elements to make the profiles meet at a simple butt joint held with pocket screws. I stop the beading on the vertical elements a bit short of where they meet the arch to leave room for carving a corner in the beading.

Are there any other options that can make sense for the small shop to shape the edge and/or to join the arch to the vertical elements, perhaps with a small miter at the bead?

I'm using 3/4" poplar with a sprayed oil paint finish.

- Jim W.

Hammond, LA

Our Expert

Curves in furniture and cabinets always present a challenge, especially when the curve has a shaped molding profile.

Here are three methods that you can choose from:

1. Shape the bead on a shaper with Amana shaper cutter no.974. To shape the bead on curved stock you'll need to construct a fence with a curved base to support the stock. The radius of the curved base is the same as the outside radius of the curved rail of the faceframe. This method is illustrated on page 194 of my book "The Complete Illustrated Guide To Shaping Wood".

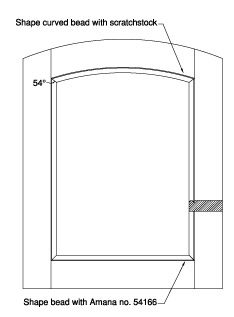

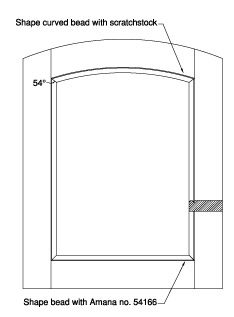

2. Shape the straight sections of bead with Amana no.54166 corner bead router bit and shape the curved bead with a scratch stock. You can purchase a scratch stock but it is very easy to make your own with an offcut and a piece of steel scraper.

3. Shape the bead and bend it to match the curve. If the radius is broad a 3/8" stick should easily bend. If not, you can steam it first. You can shape all of the beads with the Amana router bit and steam bend the curved bead. Steam bending is quite easy but you'll need to follow a few guidelines for a successful bend: Select only straight-grain stock that is completely free of knots or runout; the stick will break at a knot or split at the runout when you attempt to bend it. Small sticks, like this 3/8" bead, require about 30 to 45 minutes of cooking in a steam box. You'll have less than a minute after you pull it out of the steam box to bend it. After that it will have cooled too much to bend without breaking. Fasten the stick into the form and allow it to cool and dry. Then glue it to the curved rail. For more details on steam bending see my book that I mentioned above.

The beaded frame members can be mitered at the corners on a tablesaw. This is illustrated on the Amana website under "Articles", "Constructing a Beaded Face Frame. Keep in mind that the miter at the curved rail will not be the typical 90 degrees. You'll need to draw the curve full-size to find the miter angle.

This sounds like an exciting project and we would certainly enjoy seeing a photo of your finished work.