V-Grooving Aluminum

Our Expert

Thank you for your inquiry. Please contact the Technical department at Amana to discuss you’re application.Our Expert

Thank you for your inquiry. Please contact the Technical department at Amana to discuss you’re application.The dimensions of the drum are 17"h x 24"w. I going to try to use a single piece of plywood (can you suggest a type?) cut to 17" x 75". My question is when I cut the kerfs do I cut with the grain or across to get the best bend?

-Vikki W.

Cameron Park, CA

Our Expert

For making a decorative drum (rather than a musical drum) I suggest that you use a bendable plywood. There are a couple of brands that are readily available and I'm sure that an on-line search will reveal a source.

For making a decorative drum (rather than a musical drum) I suggest that you use a bendable plywood. There are a couple of brands that are readily available and I'm sure that an on-line search will reveal a source.

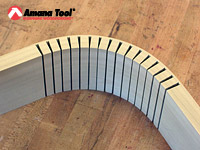

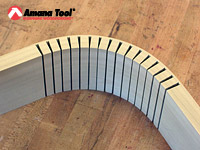

If you'd rather not use a bendable plywood then I suggest that you use solid wood and cut the kerfs across the grain. Cutting the kerfs with the grain will severely weaken the stock and it will most likely break when you attempt to bend it.

Use a combination blade such as the Amana Prestige no.PR1040 and cut each kerf through most of the stock thickness. Keep in mind that the closer you space the kerfs the more fluid the resulting curve will be; widely spaced kerfs will telegraph through the surface and make the curve appear segmented.

The dimensions of the drum are 17"h x 24"w. I going to try to use a single piece of plywood (can you suggest a type?) cut to 17" x 75". My question is when I cut the kerfs do I cut with the grain or across to get the best bend?

-Vikki W.

Cameron Park, CA

Our Expert

For making a decorative drum (rather than a musical drum) I suggest that you use a bendable plywood. There are a couple of brands that are readily available and I'm sure that an on-line search will reveal a source.

For making a decorative drum (rather than a musical drum) I suggest that you use a bendable plywood. There are a couple of brands that are readily available and I'm sure that an on-line search will reveal a source.

If you'd rather not use a bendable plywood then I suggest that you use solid wood and cut the kerfs across the grain. Cutting the kerfs with the grain will severely weaken the stock and it will most likely break when you attempt to bend it.

Use a combination blade such as the Amana Prestige no.PR1040 and cut each kerf through most of the stock thickness. Keep in mind that the closer you space the kerfs the more fluid the resulting curve will be; widely spaced kerfs will telegraph through the surface and make the curve appear segmented.

My band saw has the ability to run at two different blade speeds (1500 SFPM and 3000 SFPM). What type of applications would be best for these blade speeds?

I purchased your book on band saws and learned a lot of very useful information.

-Len R.

Franklin, TN

Our Expert

Some bandsaws are equipped with two speeds so that you can cut a wider variety of materials. The higher speed of 3000 SFPM is for sawing wood and the slower speed is for sawing non-ferrous metals such as aluminum and brass.

My band saw has the ability to run at two different blade speeds (1500 SFPM and 3000 SFPM). What type of applications would be best for these blade speeds?

I purchased your book on band saws and learned a lot of very useful information.

-Len R.

Franklin, TN

Our Expert

Some bandsaws are equipped with two speeds so that you can cut a wider variety of materials. The higher speed of 3000 SFPM is for sawing wood and the slower speed is for sawing non-ferrous metals such as aluminum and brass.

In The Bandsaw Book you recommend against using 0.025 thick blades on bandsaws with wheel diameters less than 12". I have the Ryobi 10" bandsaw

(BS1001SV) and the manual says it can handle up to 1/2" wide blades but no mention on thickness is made. Can I use 0.025 thick blades or am I stuck to the four made by Olson specifically for 10" bandsaws, where the thickness is less than 0.0250". Thanks!

-Joe

El Segundo, CA

Our Expert

As a bandsaw is running the blade is flexed around the wheels hundreds of time each minute. A blade that is too thick for the wheel diameter will break prematurely as it is repeatedly flexed around a very small radius. In order to prevent continual blade breakage, I recommend that you stick to using the thinner blades. As you've probably noticed, the thin blades flex in the cut, but that is one of the limitations of a small bandsaw. You may want to consider purchasing a larger bandsaw, such as a 14" model.

In your raised panel door video, what brand is your router table and where can I purchase one?

Thanks for your help

-Greg

Monee,IL

Our Expert

I use the Jessem MaserLift table together with the fence and leg set. The lift is built in to the phenolic top.

I am ready to finish a set of bookshelves that are made of Red Oak. The top of the bookshelf is solid oak and is attached to a piece of oak veneer

plywood. My question is; can I finish just the exposed top surface of the bookshelf or do I need to remove the solid oak top and finish both the top

and bottom? I am asking this question while thinking about wood movement and what would happen if I applied a finish to just one side of the solid oak top and if it would affect the woods ability to move equally. Thank you in advance for your response to my question.

-Stanton R.

Red Bluff, CA

Our Expert

Wood expands and contracts from summer to winter with changes in the relative humidity. As you've pointed out, it is a good idea to seal both faces of a board when finishing so that they will absorb and release moisture at equal rates. This helps to keep boards flat over the years. My own experience is that when both surfaces are not sealed the board has a much greater tendency to warp.

I suggest that you remove the solid oak top and seal the underside. Shellac works well as a sealer; it dries quickly and is easily sprayed, wiped or brushed.

I have a 5 horsepower Model 27 Powermatic shaper. It currently has a 1" spindle. 1" bore cutters seem to be getting harder to find. Amana Tool is so far the only one that I have found that still makes cutters with a 1" bore. Should I be converting to another shaft size and if so what shaft

size would I install, 3/4 or 1 1/4? I am starting a kitchen cabinet project that will use mostly tongue and groove for joints along with raised panel

cutters etc.

-Richard V.

Grass Valley, CA

Our Expert

Although my shaper has both a 3/4" and a 1" spindle, I use the 3/4" spindle most often. As you've discovered, there is often a greater selection of 3/4" bore cutters available. But more importantly, as the bore size increases the outer diameter of the cutter usually increases as well.

Larger diameter cutters require a larger fence opening which does not provide as much stock support at the point of contact.

1-1/4" bore cutters are for large production type shapers. These machines are very powerful and it is best to limit their use to a power feeder.

The operating principles for table mounted routers and shapers are the same. I think that it is best to have both a table-mounted router and a shaper. I use the router for smaller cuts and as the size of the cut increases I step up to the shaper.

I recently cut down a walnut tree. How thick would you have the boards milled if you were going to use it for 18th Century furniture?

Many thanks...........I read all of your articles that I can find (always have) and have several of your books.

-Will C.

Salado, TX

Our Expert

For 18th century furniture I use thicknesses from 4/4 to 16/4 depending upon the project. I suggest that you first start with an idea of what you'd like to build and check the finished dimensions on the drawing. To allow for milling the stock to final dimension the rule-of-thumb is to add 1/4" to the thickness.

I typically have large diameter logs sawn 5/4 for the sides of casework and tabletops. This provides wide stock that does not require gluing up to create the needed dimension. 5/4 is also needed for door frames, drawer fronts, and lids for chests and desks.

For many large moldings you'll need 8/4. Turned table legs also require 8/4. Cabriole legs also require thick stock; usually 12/4 or larger depending upon the style of the leg. Large turned bedposts often require 16/4.

When installing drawer pulls with bales, the bales seem to bind when the nut is tightened. I've tried enlarging the holes, moving one of the two holes closer to or further from the other and filing the ends of the bale so that they are smaller and more round. But as often as not. the bale is frozen in place when the nut is tightened. If I leave the nut loose, the oval rosettes rotate and scratch the finish. Any suggestions?

-Sam R.

Fort Wayne, IN

Our Expert

Authentic period furniture hardware is made using many of the same methods that were used in the 18th century. This ensures that the reproductions have the proportions, surface texture, and beauty of the originals (and sometimes a somewhat rough fit and finish).

Authentic period furniture hardware is made using many of the same methods that were used in the 18th century. This ensures that the reproductions have the proportions, surface texture, and beauty of the originals (and sometimes a somewhat rough fit and finish).

For example, inferior pulls use heavy brass wire for the bails and the backplate is stamped from thick brass. This results in a clumsy facsimile that bears little resemblance to the originals.

In contrast, the backplate of an authentic pull is made from thin brass, just like the originals. The bail is cast so that the center of the bail is thicker than the ends.

As you've discovered, sometimes the bails will bind. This does not reflect poor craftsmanship but is just a result of using authentic methods of reproduction. If you would like for the bails to swing freely I suggest that you gently bend them inwards with a small amount of hand pressure. This shortens the length of the bail between the posts.

Also, you may find that the ends of the posts extend into the drawer and can snag or scratch the drawer contents. I cut the posts flush and scoop out a recess for the retaining nut with a carving gouge.

Can you recommend a program for computer aided design to use with woodworking, cabinet making, etc? I enjoy reading the answers to all your

questions. Thank you.

-Randy O.

Marquette, MI

Our Expert

I'm not aware of a CAD program that is specifically designed for furniture and cabinet design. However, I've been using AutoCAD Light for many years now and I'm sold on the program. The light version has everything that full-blown AutoCAD does but 3D and yet it is just a few hundred dollars (compared to thousands for the full version). You might also check into SketchUp which is a cad program which you can download for free.

Most computer aided drawing programs have a bit of a learning curve but the time is well-spent. Drawing with CAD is much faster and more accurate than by hand. And making design changes is a snap compared to using pencil and paper.

I am in the process of building exterior raised panel wooden shutters. My question has to do with my router's HP. I have a Bosch 1617EVS router with

2-1/4 HP. I was told that I should be getting at least a 3 HP router for shaping the raised panels (with the back cutter). I have 40 shutters to

build.

Is my router's HP sufficient?

Another suggestion was to use a vertical raised panel router bit.

-Andre B.

Steger, MN

Our Expert

Over the past twenty years the selection of router bits has tremendously expanded. There are many things that you can do today, such as shaping a raised panel, that once required a shaper.

However, the large bits require a large router to spin them. I suggest that you use a vertical raised panel bit - Amana Tool no.54524, or you invest in a large router. Running a horizontal router bit in a 2-1/4 HP router will push it beyond it's limits

I have an old sears craftsman shaper model #11323930, mfg #2876. Is there a replacement spindle or adapter I can put on this to allow it to accept router bits with a 1/2 inch shank? thanks.

-Sergio

Steger, MN

Our Expert

I doubt that Sears made an adapter for that machine but I suggest that you go to Sears and ask. Even so, you'll find that the shaper runs too slow for all but the largest diameter router bits. As a rule-of-thumb, shapers spin at 10,000 RPM and the RPM of most routers is 10,000 to 21,000. Although it works to spin small router bits in a shaper, you'll need to dramatically slow the rate at which you feed the work past the bit. I suggest that you purchase a large, variable speed router and mount it in a table.

I doubt that Sears made an adapter for that machine but I suggest that you go to Sears and ask. Even so, you'll find that the shaper runs too slow for all but the largest diameter router bits. As a rule-of-thumb, shapers spin at 10,000 RPM and the RPM of most routers is 10,000 to 21,000. Although it works to spin small router bits in a shaper, you'll need to dramatically slow the rate at which you feed the work past the bit. I suggest that you purchase a large, variable speed router and mount it in a table.

I just received my Amana 55340 router bit. Unfortunately, my router (Porter-Cable 690) is fixed speed at 23,000 rpm and the bit came with instructions to run the bit at max 16,000 rpm. Porter-Cable does not recommend using an accessory variable speed controller as it may harm the motor. So, can you give me some information about why the limit on this particular router bit needs to be run at 16,000 rpm max.? I only have a single window to make currently and wish not to invest in a larger router with speed control.

Thanks for any insight you might give.

-Ray

Seattle, WA

Our Expert

Large diameter bits have a higher rim speed than small diameter bits when run at the same RPM. Running any router bit at speeds beyond the manufacturer's suggested RPM is a risk to your personal safety. The fact is, to safely use many of today's large diameter router bits you'll need a powerful variable speed router and a router table.

Large diameter bits have a higher rim speed than small diameter bits when run at the same RPM. Running any router bit at speeds beyond the manufacturer's suggested RPM is a risk to your personal safety. The fact is, to safely use many of today's large diameter router bits you'll need a powerful variable speed router and a router table.

The good news is that there is a wider assortment of router bits than ever before. In fact, these days you can make many cuts with your router, such as raised panels, that once required a large, expensive shaper.

I am needing to draw an eliptical arch . I've drawn one using 1 large arc & two small arcs and it looks almost correct but tell me the best and fastest way to do this . I've read some on your suggestions in some publications using a trammel w3 points but I don't fully understand. By the way the width I'm dealing with is 50" and the height is approx. 10" to 12"

-Steve S.

Vian, Ok

Our Expert

Drawing an ellipse is just a step beyond drawing a circle. To draw a large diameter circle I use a pair of trammels clamped to a stick.

Drawing an ellipse is just a step beyond drawing a circle. To draw a large diameter circle I use a pair of trammels clamped to a stick.

To draw an ellipse I use a third trammel. When drawing a circle one point remains in a fixed position at the center of a circle. However, when drawing an ellipse all three trammel points move; two points move along the edge of a large square object, such as a framing square or sheet of plywood while the third point draws the ellipse.

Begin by positioning the trammels on the stick. The trammel with a pencil is positioned at one end. The remaining two trammels are positioned at a distance from the first equal to the major and minor axis of the ellipse. Now you're ready to draw the ellipse.

Two of the trammels are guided by a ninety degree object, such as a framing square. Clamp the square securely to the bench top so that it remains in a fixed position. As you guide the two points along the edge of the square, the third point will draw one-quarter of the ellipse.

i need to rout wide grooves to accept router inserts i am doing this on my existing router table when i move the fence to widen groove the next cut is a bit deeper or shallower any ideas why this is happening.

-Larry

Rogers, MN

Our Expert

When making multiple passes with a straight bit it is typical to see slight variations in groove depth. There are a number of factors that contribute to this. For example, a router table top that is not flat, a router base that is not perfectly flat, deflection of the workpiece or slight unevenness in the stock being routed can all create minor variations in cutting depth. In fact, variations of as much as .003" to .004" in adjacent grooves are not unusual when hand routing. Greater precision would require a computer controlled router (CNC).

If you're experiencing more than .003" or .004" variation it could be caused by debris between the workpiece and the registration surface. Try using dust collection and sweeping the top of the router table between cuts.

I am building a Coffee Table from "red gum" to match existing trim ia a clients house. The Red gum that i have purchased is very brown and the customers wood has a reddish hue. The saw the wood being re-fnished and say there was only several coats of Oil applied. Do you know if Red gum will change color with time?

-Kenny B.

Memphs, TN

Our Expert

All the woods that I've used in woodworking change color with time and exposure to sunlight. For example, in just twelve months cherry changes from a pink salmon color to a deep, rich reddish brown. Walnut starts out with a dark chocolate brown color and lightens with more reddish and yellow tones. Although I've never worked with red gum I suspect that it changes, too. As a

rule-of-thumb light woods such as maple darken with time and dark woods become lighter.

When color matching new wood to match aged wood I use aniline dyes. I'll usually start out by bleaching a dark wood, such as walnut, with two-part wood bleach to provide a more neutral base for the dye. You can find wood bleach at most paint and hardware stores. After bleaching I apply the dye and then a top coat. Dyes are available in dozens of shades and I just

experiment on offcuts to find a color that matches the aged wood as closely as possible.

I'm building a china hutch for my mother. I began the project last fall and completed most of the bottom piece including the carcass, 5 drawers and two doors. The piece is made of 1/4" sawn sapele. Drawer frames are 4/4 pine. The top is joined to the sides with dovetails. After breaking from the project all summer I was dissapointed to find that the sides of the case have bowed slightly, causing what was my best set of dovetails yet to look less than beautiful. I may have caused the problem by gluing the drawer spacers to the case sides.

Do you have any suggestions that may help me remedy this problem?

-Seth H.

Cove, OG

Our Expert

Unfinished wood can warp dramatically when it is exposed to changes in relative humidity. The warp may occur over a period of weeks or just a couple of days. To prevent stock from warping here are the steps that I take:

1. I use wood that is in equilibrium with the environment in which it will be placed. In other words, I use dry wood. For furniture and cabinets that will be used indoors in a controlled environment (forty percent relative humidity) seven percent moisture content is ideal. If the moisture content is too high the wood will release moisture and warp.

2. I mill the stock only when I'm ready to use it. For example, when making paneled doors I don't mill the panel until I've constructed the frame. Once I flatten the panel stock and plane it to thickness I immediately fit it into the door frame. The framework will help to keep the panel from warping.

3. I apply finish to the work as soon as possible. Finishes don't stop moisture exchange but they slow it down dramatically. And remember, it is important to apply finish to both sides. If one side is left unfinished it will absorb moisture at a faster rate and cause warping.

These are solid guidelines that I use when working with wood. However, sometimes things don't always go as planned. For example, years ago I was constructing a dining table for our kitchen. The figure in the wide tiger maple boards popped as I applied the finish. In my excitement I neglected the underside of the table top. That night the relative humidity changed dramatically as a storm passed through the area. When I entered the shop the next morning the top had severely cupped despite the large breadboard ends. To correct the problem I placed the top outdoors in direct sunlight with the unfinished convex side facing up. After about forty-five minutes in the bright sunlight the top had dried out and it was flat once again. I quickly sealed the surface with a couple of coats of finish. Years later it is still flat.

I suggest that you try a similar remedy by applying moisture to the concave side while applying heat to the convex side.

I recently broke a motor pully on my old table saw and had to replace it with one a half inch larger. Pullys on the saw were 2.5 in. Now the motor pully is 3.in. It certainly spins a lot faster, will it impair cutting performance? Safety? Motor is 1 hp ,3450rpm, blade is 9inch.

-Joe M.

La Quinta, CA

Our Expert

When replacing worn or broken pulleys on woodworking machinery it's important to use a replacement pulley that matches the original. For your personal safety you should never exceed the manufacturer's recommended RPM for a sawblade, router bit, shaper cutter or other cutting tool.