Hi I'm makng a 6'-8" tall X 2'-8" wide entry door using the Amana Tool no. 47511 stub spindle and cope cutter. Can you suggest a width for the stiles and rails?

- Nezaam

Hi I'm makng a 6'-8" tall X 2'-8" wide entry door using the Amana Tool no. 47511 stub spindle and cope cutter. Can you suggest a width for the stiles and rails?

- Nezaam

Our Expert

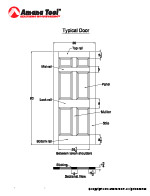

The door that you are making is only slightly narrower than a standard entry door. In order to keep the stiles and rails proportional to the overall door that you shave an inch or so from the standard widths shown on the drawing.Otherwise the door panels may appear too large in proportion to the stiles.

The door that you are making is only slightly narrower than a standard entry door. In order to keep the stiles and rails proportional to the overall door that you shave an inch or so from the standard widths shown on the drawing.Otherwise the door panels may appear too large in proportion to the stiles.

This is my first attempt anything like this; I've ordered a router and table just for this project. Using 3/4" stock and looking at bit set 49680 or 49682 will I have the room on the stiles and rails to make the rabbet cut for my panels? I'm not sure how to read the measurements for the bits. A quick answer would be greatly appreciated so I can get started.

- Bob

Moorestown, NJ

Our Expert

Wainscot is a good "first woodworking project" to get you introduced to the tools and the various cuts. You mentioned that you have purchased a router but no mention of a router table. There are many good ones on the market; I prefer one with a lift because it makes accurate set-ups much faster and easier. Setting up the router carefully is the key and using a test piece is essential to good results.

To make the wainscot in the article I used Amana Tool Wainscot set no.49684. To create the chair rail I used no.54266. The panel was shaped with toolno.54117

I need to make an applied wood grill for a large window that was broken. The existing grill is made of pine roughly 3/4" square stock. The intersections are joined with half-laps. What tooling do I need to make the half-laps and to profile the long edges?

- Terry

Allison Park, PA

Our Expert

Historically speaking, architectural window sash as well as doors on furniture and cabinets had narrow strips of wood, called mullions, that separated the relatively small individual panes of glass. Presumably, small panes of glass were used because the technology was not available to make larger pieces. However, there is a definite appeal to the small panes that persist to today to the point that large windows are covered with a fake grillwork to simulate a real divided light sash.

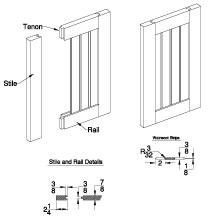

A true divided light sash or door is a framework of narrow strips of wood which are "stuck" (hence the term sticking), or shaped, on the face for decoration and rabbeted on the back to accept glass panes. The strips are usually joined with mortise-and-tenon or half-lap joints. Where the sticking intersects it must be mitered or coped. True divided light window sash and cabinet doors are beautiful but a lot of painstaking work involving several careful steps to ensure that all the parts fit during assembly.

A true divided light sash or door is a framework of narrow strips of wood which are "stuck" (hence the term sticking), or shaped, on the face for decoration and rabbeted on the back to accept glass panes. The strips are usually joined with mortise-and-tenon or half-lap joints. Where the sticking intersects it must be mitered or coped. True divided light window sash and cabinet doors are beautiful but a lot of painstaking work involving several careful steps to ensure that all the parts fit during assembly.

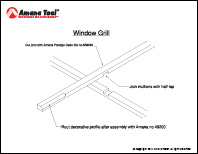

An easiest solution to making a decorative grill is to simply join the mullions with half-lap joints and rout a decorative chamfer or roundover profile on the mullions after assembly.

I'm using the Amana bead wainscott panel router bit set which includes bits no. 49640, 49642 and 54266. What thickness stock should I be using with the bits? I think 3/4 is too thick, what is recommended 1/2 inch? Also any tips on setting the router bit height?

Ken

Our Expert

Amana has three router bit sets, the bead, bevel and ogee, for constructing traditional paneled wainscot, each of which are designed to add beautiful architectural details to a room. Like traditional paneling, the sets are designed for 3/4" thick stock to provide the necessary visual effect as well as to provide the space needed for a chair rail

Amana has three router bit sets, the bead, bevel and ogee, for constructing traditional paneled wainscot, each of which are designed to add beautiful architectural details to a room. Like traditional paneling, the sets are designed for 3/4" thick stock to provide the necessary visual effect as well as to provide the space needed for a chair rail

To set the router bit depth, begin by setting up the sticking, or bead bit, to a height that provides a sufficient fillet, or flat area, above the bead. Then set the matching cope bit to correspond.

I have a pair of French interior doors to build (1-3/4" thick). I'm wondering what bit set you would recommend to produce, with a minimum of set ups, true divided light doors?

Rob

Our Expert

The Amana no.55340 is a good choice because it is easy to set up and it provides a rabbet for glass. With this tool you can construct a true divided light door 1-3/4" thick.

The Amana no.55340 is a good choice because it is easy to set up and it provides a rabbet for glass. With this tool you can construct a true divided light door 1-3/4" thick.

For a stronger door with mortise-and-tenon joinery you can use the Amana Entry Door Cope Cutter Bits numbers 54131 and 47511. By cutting the ogee profile on one face of the door and a rabbet on the opposite face glass can be used in the place of wood panels. This construction will require more time than bit no.55340 but the joints are stronger because they have more surface area for glue.

I will be gratefull if you can advice me on moulding wood over round concrate pilar. whch Amana tools will you suggest.

London

Our Expert

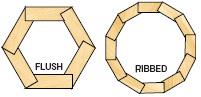

Amana makes several Multi-Sided Glue Joint bits #54274. Depending upon the bit that you select, you can construct a hollow column with 6, 8, 12, or 16 sides. The unique design of the bits makes it easy to align the parts during glue-up.

Amana makes several Multi-Sided Glue Joint bits #54274. Depending upon the bit that you select, you can construct a hollow column with 6, 8, 12, or 16 sides. The unique design of the bits makes it easy to align the parts during glue-up.

I am replacing my mother-n-law's roof. The roof/ceiling (no insulation) was made with 2x8 (1 1/2"x 7") tongue and groove w/ chamfered edge. The one side was planed and chamfered to provide a finished ceiling. The other side was left raw and just roofed over. This profile isn't available any more.

I am trying to find router bits to recreate the boards to replace rotted boards in ceiling. Mom doesn't want to change the look of the roof/ceiling... Help!

Many thanks!

- Terry

Phillipsville, CA

Our Expert

Amana offers several excellent tongue-and-groove router bit sets such as no. 55405. However, because of the stock thickness of 1-1/2" I recommend the Amana Quadraset no. 53600. This router bit comes equipped with four cutters that stack on the arbor. By arranging the cutters you can create grooves from 1/8" to 23/32". After routing the tongue-and-groove joints you can shape the chamfered edge with Amana no. 49404 chamfer bit.

Amana offers several excellent tongue-and-groove router bit sets such as no. 55405. However, because of the stock thickness of 1-1/2" I recommend the Amana Quadraset no. 53600. This router bit comes equipped with four cutters that stack on the arbor. By arranging the cutters you can create grooves from 1/8" to 23/32". After routing the tongue-and-groove joints you can shape the chamfered edge with Amana no. 49404 chamfer bit.

To make the fluted panels on the boxed newel would you use a router bit or shaper? If router bit which one and how do you get it so it doesn't rip your wood? How do you get it to stop in the middle of the newel? We are making the 3 flutes on each side of the newel. We want to make them ourselves instead of spending the $200.00 each to buy them.

- Shelly P.

Rochester, MN

Our Expert

I recommend that you use the router. Router bits are less expensive than shaper cutters and you can choose any flute spacing that you prefer. Amana makes a complete selection of core box bits, such as no.45924.

Regardless of the type of cut, router RPM and feed rate are important for creating a smooth surface. If the surface appears rough, increase the RPM and/or slow down the feed rate.

In order to cut flutes in a box newel you'll need a fence attachment for the router to guide it in a path parallel to the edge of the stock. Layout the starting and stopping points of the flutes and simply run the router between the layout lines. If you prefer, you can clamp a strip of wood to the workpiece to stop the router, but it's not necessary.

I am building hickory kitchen cabinets for a customer. These doors and panels have a solid 3/8" hickory insert with 1-5/8" center bead milled into them. Customer wants to the door panels to match their wainscoat paneling. I've considered using a subcontractor for the doors. The subcontractors price was $72 per piece; each piece measures 24" x 30". I thought the price was high and so I considered making the panels myself. To make the panels I need a molding head for tablesaw. However, I'm having difficulty finding a bead cutter for a tablesaw.

Before shaping I will have to glue the hickory stock edge-to-edge and sand the panels smooth. A local architectural millwork shop can help me by gluing up solids in a high frequency machine, but he does not have tooling to run bead. If you have any ideas or comments I sure could use them.

- Jay

Skiatook, OK

Our Expert

When constructing architectural woodwork to match existing woodwork in a clients home, I have found that it's often necessary to purchase custom tooling for the shaper, tablesaw or other machine. If so, I add the cost of the tooling to the price of the job when I submit a bid. This allows the customer to decide whether they want to cover the additional costs of custom tooling or settle for a profile that may be close but not a perfect match. Usually the desire for a perfect match diminishes when the customer realizes the price for expensive custom tooling.

Regarding the $72 per panel price quoted to you, I suggest that you first factor all of your costs. You may not be substantially ahead by the time you factor your labor, materials, and the costly overhead associated with running a woodworking shop. In fact, subcontracting this part of the job may increase your profit margin. Many cabinet shops outsource the doors and drawers to shops that specialize in this time-consuming part of the job.

Regarding the $72 per panel price quoted to you, I suggest that you first factor all of your costs. You may not be substantially ahead by the time you factor your labor, materials, and the costly overhead associated with running a woodworking shop. In fact, subcontracting this part of the job may increase your profit margin. Many cabinet shops outsource the doors and drawers to shops that specialize in this time-consuming part of the job.

If you decide to make the door panels yourself, I suggest that you do not glue together the strips. Originally the bead on paneling was used to hide the tongue-and-groove joint between the mating wood strips. The tongue-and-groove joint is necessary to allow for seasonal expansion and contraction of the solid wood. If you wish to use a solid panel I recommend that you use a hickory veneered plywood for stability.

Amana has shaper cutters for creating beaded paneling. Cutter set no.SC430 is provides an attractive traditional profile. Using this set, there is no need to glue the panels edge-to-edge. Instead, the set creates a tongue-and-groove joint along the edges of the strips. This design will also allow for the seasonal expansion and contraction that will occur in natural hickory.

Ok, I may have gotten in to deep on this one... here's my problem any help would be appreciated.

I have large window with a half round top, the glass was broken and needs to be replaced. The local glass guy can make the glass but not the removable grill that was also destroyed. The window is 5 feet wide by 7 feet tall, and is a true radius. I wanted to make removable grills that snap in for easy cleaning... I've found a few router bits that get me close but not home... any suggestion on which bits to use, and how to get started. I hope this makes sense. Thanks

- Gene

Huntington, CT

Our Expert

Historically speaking, architectural window sash as well as doors on furniture and cabinets had narrow strips of wood, called mullions, that separated the relatively small individual panes of glass. Presumably, small panes of glass were used because the technology was not available to make larger pieces. However, there is a definite appeal to the small panes that persist to today to the point that large windows are covered with a fake grillwork to simulate a real divided light sash.

A true divided light sash or door is a framework of narrow strips of wood which are "stuck" (hence the term sticking), or shaped, on the face for decoration and rabbeted on the back to accept glass panes. The strips are usually joined with mortise-and-tenon or half-lap joints. Where the sticking intersects it must be mitered or coped. True divided light window sash and cabinet doors are beautiful but a lot of painstaking work involving several careful steps to ensure that all the parts fit during assembly.

A true divided light sash or door is a framework of narrow strips of wood which are "stuck" (hence the term sticking), or shaped, on the face for decoration and rabbeted on the back to accept glass panes. The strips are usually joined with mortise-and-tenon or half-lap joints. Where the sticking intersects it must be mitered or coped. True divided light window sash and cabinet doors are beautiful but a lot of painstaking work involving several careful steps to ensure that all the parts fit during assembly.

An easiest solution to making a decorative grill is to simply join the mullions with half-lap joints and rout a decorative chamfer or roundover profile on the mullions after assembly.

Are the Wainscot Shaper Cutters available for 1/2" thick stock?

- Frank P.

Casablanca - Chile

Our Expert

In order to reduce costs many traditional architectural molding profiles have been reduced in thickness. While reducing stock thickness saves material costs, it also distracts from the beauty and authenticity of the original profiles. As a result, many once beautiful moldings, such as crown and wainscot, are shallow and lack the appeal of the originals. For example, if we design the cutters for 1/2" thick stock the material thickness is reduced by 1/3, a substantial amount. This would require that we use a flattened bead and a shallow vee and/or use a thin and very weak tongue-and-groove joint.

In order to reduce costs many traditional architectural molding profiles have been reduced in thickness. While reducing stock thickness saves material costs, it also distracts from the beauty and authenticity of the original profiles. As a result, many once beautiful moldings, such as crown and wainscot, are shallow and lack the appeal of the originals. For example, if we design the cutters for 1/2" thick stock the material thickness is reduced by 1/3, a substantial amount. This would require that we use a flattened bead and a shallow vee and/or use a thin and very weak tongue-and-groove joint.

However, one solution is to simply eliminate the tongue-and-groove joint along the edge of each wainscot strip and use a ship-lap joint instead. This option will allow you to use thinner material and keep the authentic profile.

Help! I'm making 2-1/4" thick frame and panel entry doors with cope, stick and tenon joinery. Can I use the new Amana cope bit #47511 and the matching ogee bit#54131 that Amana recommends for 1-3/4" thick doors?

Seems to me that I could, with the difference being a wider tenon and wider groove. In this case up to 1/2" wider it seems. I'm having difficulty determining if there are limitations imposed by the bits, your insight will be greatly appreciated!

- Rick

Kaneohe, HI

Looking for info - how to - what tools tecniques for making window parts, Mullions and Muntins.

- Thomas

New Orleans, LA

Our Expert

Amana has two sets of bits for creating windows with divided lights. The first, nos.55340 and 55341 work with stock from 1-1/8" to 1-3/4" thick.

Amana has two sets of bits for creating windows with divided lights. The first, nos.55340 and 55341 work with stock from 1-1/8" to 1-3/4" thick.

The second set, Amana Tool no.55360, is designed to shape the muntins and mullions with real mortise-and-tenon joinery. This set works with stock from 3/4" to 7/8" thick. Amana will soon come out with a larger version of this set for thicker stock.

All of the sets come complete with step-by-step instructions.

I can't find a triple fluted router bit big enough to run grooves in 3-1/2" wide window trim. Ideally the carbide cutters would be a total of 3" wide to leave 1/4" on each side of the 3-1/2" trim. Is there such a bit? or do I need to look into the world of shaper cutters?

- Jeremy

Hope, ME

Our Expert

Fluting is a traditional decoration which consists of a series of semi-circular grooves cut into a column or pilaster (a flat column applied to a surface). Fluting has a wide variety of applications and is used in both furniture and architectural woodwork and even kitchen cabinets.

Fluting is a traditional decoration which consists of a series of semi-circular grooves cut into a column or pilaster (a flat column applied to a surface). Fluting has a wide variety of applications and is used in both furniture and architectural woodwork and even kitchen cabinets.

Traditional fluting is spaced so that the spaces between each flute is less than the flutes that flank it. The flutes can run the entire length of the piece to which they are applied or, for added visual interest, they can be stopped at each end. For even greater detail, the ends of the flutes at the base can be carved with a reverse profile.

To create a production run of fluted pilasters the most efficient option is to use a shaper and power feeder. The workpiece is positioned on edge and a wide cutter is used which cuts all of the flutes at once. However, using the shaper for fluting has it's disadvantages, too; the size and spacing of the flutes is limited to the shaper cutter and it is not practical to stop the flutes when using a shaper.

In contrast to the shaper, a table-mounted router and a core box bit, such as Amana Tool no.45946, allows much greater flexibility in the size and spacing of the flutes. Additionally, the router and a core box bit makes it much easier to stop the flutes instead of running them through.

I need a Router Bit that I can use to make transition moldings for 3/4" hardwood flooring. I need something that will give me a gradual rounded profile. A round over bit makes a profile that is too round. Any suggestions would be appreciated.

- Dan F.

Allen, TX

How to cut returns on stair treads?

- Paul D.

Melville, LA

Our Expert

On today's stairs, a stair tread return is a decorative strip of wood that is applied over the end grain on the open end of the tread. However, on traditional stairs the returns also served to hide the baluster joints from view. Originally the end of each baluster was dovetailed to the stair tread for strength and longevity. A single dovetail on the end of each baluster was carefully fitted to a dovetail socket on the end of the tread. Afterwards the return was applied to hide the joinery. Unfortunately, unless you purchase a custom made stair, today's balusters are simply attached to the tread with a dowel. As you might imagine, unlike a dovetail joint, the round pin or dowel lacks resistance to leverage and torque. As a result, most stair handrails become loose after just a few years.

On today's stairs, a stair tread return is a decorative strip of wood that is applied over the end grain on the open end of the tread. However, on traditional stairs the returns also served to hide the baluster joints from view. Originally the end of each baluster was dovetailed to the stair tread for strength and longevity. A single dovetail on the end of each baluster was carefully fitted to a dovetail socket on the end of the tread. Afterwards the return was applied to hide the joinery. Unfortunately, unless you purchase a custom made stair, today's balusters are simply attached to the tread with a dowel. As you might imagine, unlike a dovetail joint, the round pin or dowel lacks resistance to leverage and torque. As a result, most stair handrails become loose after just a few years.

To cut the space on the end of a tread for a return you'll need to make a mitered stop cut on a tablesaw. I recommend using Amana Tool saw blade no.610800 to cut the miter. Afterwards, use the same blade to make a stopped crosscut. Because the curvature of the saw blade prevents the cuts from completely intersecting at the corner, you'll need to finish the cuts at the intersection by hand.

An alternate method is to use a router and template. Instead of a true miter a curved intersection is used instead. First remove most of the waste with a jigsaw and complete the cut with Amana Tool no.47141 flush trim bit and a

An alternate method is to use a router and template. Instead of a true miter a curved intersection is used instead. First remove most of the waste with a jigsaw and complete the cut with Amana Tool no.47141 flush trim bit and a

template.

To make the bullnose shape on the edges of the treads I use Amana Tool no.51562 bullnose router bit.

I am building replacement sashes on a window that is 7/4 in thickness, is there a router bit window set that can cut that or is that a better alternative. I am thinking at this time of milling as much as possible with the table saw and then finishing with router bits for the various profiles, the problem is joining or coping the rails and stiles.

- Joseph

Chesnut Ridge, NY

Our Expert

-th5d130869.jpg) Yes, Amana Tool no.55340 is designed specifically for shaping and coping 1-3/4" window sash. It has an ogee profile and also cuts the rabbet for the glass.

Yes, Amana Tool no.55340 is designed specifically for shaping and coping 1-3/4" window sash. It has an ogee profile and also cuts the rabbet for the glass.

I have a full wall built-in bookcase that I'm refinishing. I'm putting oak crown on the top and staining it walnut. I would like to put mdf crown

around the other walls and paint it.

How do I tie the mdf into the Oak? They are both about 4 1/2" but completely different profiles. Should I just stop short of the oak about 6 inches and do a crown return back to the wall.

- Dan H.

Mission Viejo, CA

Our Expert

Built-in furniture is considered part of the room and is usually finished to match the woodwork in the room. However, if you choose to use a painted finish on the woodwork your solution to return the crown molding to the wall should keep the two moldings visually separate. I doubt that the bookcase will appear built-in though.

In reference to your Constructing Wainscot article, what bits where used to create the look in Photo A (the raised panel wainscot)?

- Robert

Troutville, VA

I have seen your divided light router set.. and was wondering if you feel that it is possible to use this set to build divided light windows in a house. I live in Barbados and the cost of pre-built windows is very expensive and the windows are inferior. Also, they don't build casement windows. Also would one set hold up to build 20 windows out of either purpleheart ot greeheart wood?

Barbados

Our Expert

Yes, the Amana Tool Divided Light Door Set no.55360 should work fine for casement windows as long as you're using standard glass panes. Keep in mind that the set works with stock up to 7/8" thick so if you plan to use thick insulated glass there may not be enough space in the rabbet which holds the glass.

Because the set uses real mortise-and-tenon joinery, doors and windows made with this set are very strong and, unlike sets which use a short faux tenon, will resist sagging over time.

All Amana router bits use carbide cutting surfaces, either brazed carbide, carbide inserts, or in the case of spiral bits, solid carbide. Carbide is

extremely long-wearing and so the Divided Light Door set will easily shape the parts for twenty windows made from a tropical wood.